KLA CDSEM

We offer refurbished KLA CD-SEM systems and associated spare parts with the largest inventory in the market. This product line is supported from our operations center in Blackwood, NJ USA. This location houses a 2500 SqFt metrology refurbishment lab within 12,000 SqFt facility.

Why GCE ?

- Proven solutions for Si, GaAs, SiC, Sapphire, Glass, and other exotic substrates

- Wafer Size Options: 3" - 8" (smaller substrates run with carrier wafer)

- Run variety of wafer sizes & types on the fly. No hardware changes = zero downtime !

- Each CD-SEM configured and optimized for customer's specific application

- Performance guaranteed to be in full compliance with original new tool specification

- Installation, warranty, training, and after sale support offered worldwide

- Comprehensive spare parts program with spare parts available to ship immediately

- More than 50 CD-SEMs deployed for fabs in US, Europe, Russia, Taiwan, China, Brazil

- High level factory trained senior engineers on staff full time

- The largest inventory worldwide of KLA 8xxx CD-SEMs and spare parts for sale

Re-engineered by GCE as the most versatile CD-SEM solution in the market !

Talk to us before selecting CD-SEM platform for your fab.

Featured KLA CDSEM

| Image | Model | Description | Qty |

| 8100XP CD-SEM | Res: 4nm, Features: 30nm, 3"-8" wafers, Mag: 400kx | 3 | |

| 8100XPR CD-SEM | Res: 4nm, Features: 30nm, 5"-6" reticles, 3"-8" wafers, Mag: 400kx | 2 | |

| 8250 CD-SEM | Res: 4nm, Features: 30nm, 3"-8" wafers, Mag: 400kx | 2 |

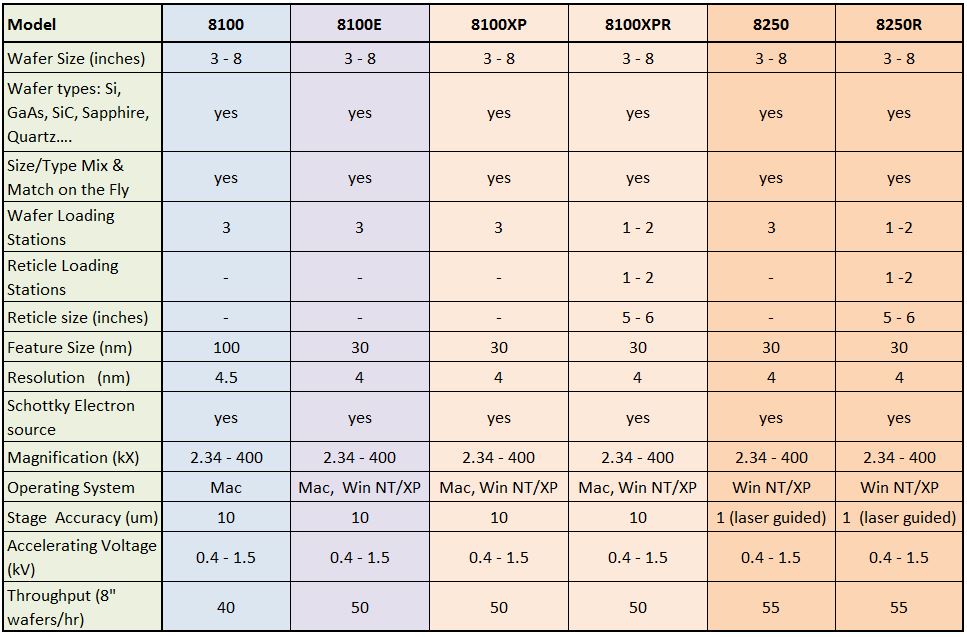

KLA CD-SEM Selection Chart:

Our Refurbishment Process:

- New electron source

- All main power modules are refurbished and tuned for optimal performance (Shottkey gun controller, Detector controller, DC power supply, & Wein Filter)

- Robot, robot controller, & pre-aligner rebuilt and re-calibrated

- Chamber vacuum feed through assemblies replaced with new

- Stage motors replaced, X and Y

- All consumables replaced (Apertures / scintilator, etc)

- End effector inspected and replaced if required

- Turbo pump rebuilt

- Both scroll pumps fully rebuilt

- All mechanical assemblies inspected and repaired/replaced, as required.

- All wiring and tubing inspected and repaired/replaced, as required.

- Each load port is calibrated to run customer specified wafer size(s). Pipe line cycle tests are run to ensure flawless operation in full automation.